FAQs

Q: What if I cannot find my moulding profile in your catalog or on your website?

Our catalog and our website show only a small fraction of our total mold inventory (we have over 50,000 profiles and add 5-10 new profiles/day). Fax or e-mail us a tracing of the profile you need to match (including the dimensions of the profile) and if possible, please provide the name of the wood moulding manufacturer/distributor. If we do not have a match (or something that is close), we can easily replicate any profile (in to flex) if you can send us two 7’ pcs of wood (or a single 13 ft piece if the piece is being stained) in order to make a 12” mold. Tooling charges (if required) vary depending on the size of the moulding and the shape of the profile. Please contact our office for details.

Q: Will the flexible moulding match my wood moulding profile exactly?

We use the actual wood moulding that is sent to us to make our molds. Our molds will replicate the original shape and grain of the wood (oak, mahogeny, finger joint, etc.) EXACTLY and our material is paintable or stainable (you need to use a “gel” type stain if it is being stained). One of the key issues to consider (in trying to match a profile exactly) is that we have found that the dimensions of the wood moulding can vary slightly (for the same profile) from supplier-to-supplier and from mill-to-mill. Therefore, in order to insure the best match, please provide information as to which company supplied the wood moulding that you are trying to match, the species of wood (if applicable), and whether it is MDF, finger joint, or clear. In the case of any uncertainty, you can always fax our office a tracing of the profile along with the dimensions in order for us to ensure that the moulding matches exactly.

Q: Can you make custom moulding patterns?

Our “Made to Match” manufacturing process allows us to replicate ANYTHING (wood moulding, decorative profiles, corbels, onlays, etc.). We have done many historic restoration projects, including the Turkish Embassy in Washington, DC where we reproduced 100 year old mouldings that were no longer available.

Q: Will a straight piece of flexible moulding work for my application? Can I bend it on the jobsite to my curve?

One of the most common questions that we hear is "will a straight piece will work for a curved application?" In general, the amount of flexibility in the moulding (i.e., whether a straight piece can be used) is determined by the following:

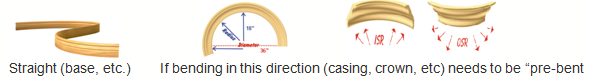

- A) Direction the profile is being bent:

- B) Application – Here are some general guidelines that can be used:

- 1. Base – Typically installed with the back of the moulding to the wall so a standard straight flexible piece can be bent on the jobsite.

- 2. Chair Rail – Typically installed with the back of the moulding to the wall so a standard straight flexible piece can be bent on the jobsite.

- 3. Crown – Most crown moulding must be pre-bent but this depends on both the size of the crown itself, the radius of the curve and its application. See "Ordering Crown" section for more information.

- 4. Jamb – A straight flexible piece can normally be used.

- 5. Small Profiles (Corner, Shoe, Cove, Base Cap, Quarter Round, etc) – These items are generally very flexible and only require pre-bending when used on a tight radius application of 3” or smaller.

- 6. Panel Mould - A straight piece can be used along a curved wall but the moulding may need to be pre-bent for other applications. Contact our sales department for clarification.

- 7. S4S (Flat Stock) – Depends on size of the piece and the application. When used as a base, jamb, or jamb extension a straight piece will work. If used as casing over an arched window, the part must be pre-bent at the manufacturing plant.

- 8. Brick Mould – Depends on how the moulding is being used (if casing, generally needs to be pre-bent).

- 9. Casing - Depends on the thickness and width of the profile (see below) and the radius of the curve. See "Ordering Casing" section for more information.

- C) Profile Size - You can generally compare the flexibility of a piece of polyurethane moulding to a piece of rubber – the thicker and wider the piece is, the harder it is to bend and vice versa.

- a. For a small piece of moulding (like a shoe mould), the piece will bend very easily and a straight piece will work for most applications.

- b. For a larger piece of moulding (like a base or casing), the moulding will bend easily in the direction of the thinner dimension (like base on a curved wall) but will be more difficult to bend in the direction of the wider dimension (like casing over an arched doorway).

- D) Shape (Half Round, Arch, Elliptical, etc.)- Straight pieces can generally only be used for larger true radius arches but the ability to use a straight piece is determined by how large the radius is versus the width of the profile. For example, for a 2 ¼" casing, a straight piece will work if the radius is greater than 72." Half rounds, ovals, and ellipticals will generally always need to be pre-bent unless it is a very small profile.

Q: How do I place an order?

Orders can be placed via phone fax, or email to either our NC or UT facilities. Our order forms are available for convenience but are not required. If you have never placed an order with us in the past, we will need a completed “Credit Application” in order to set up your company properly in our system. Please note that we do not sell directly to builders or homeowners because we would tthen be competing against our regular customers - who are building supply/millwork wholesalers and retailers. We will be happy to provide the name of a local retailer or you can also place orders through our on-line distributors (www.flexiblemillwork.com and www.trimster.com).

Q: Do you have an order minimum?

Our minimum order size is 4 feet of material and we can easily accommodate any order size from one piece to hundreds of pieces.

Q: What are your lead times?

Stock orders ship within one day and custom orders generally take one week or less to complete. Larger orders may take additional time but we will let you know at the time of order placement if the order will take longer than our standard one week lead time (In general, the lead time is dictated by how many molds we have for a profile versus how many pieces are ordered).

Q: How does it ship?

Most orders are shipped via UPS Ground. Larger orders will ship via common carrier. All our flexible moldings ship rolled up in a square box that measures around 16-28” in size.

Q: Can this product be used for interior and/or exterior applications?

Yes, this product is stable and will not absorb moisture and is ideal for humid environments. It is not affected by heat or cold and can withstand extreme environments.

Q: Do I need special tools for installation?

Conventional woodworking tools can be used with this material. Always install moulding in a relaxed position. Use construction or panel adhesive continuously on the backside and nails to secure moulding in place until adhesive bonds. Remember – do not use staples to fasten material, keep nails to a minimum (no closer than 6 inches between nails), and do not nail closer than 3/8 inch from edge of moulding.

Q: Can it be painted and/or stained?

All of our material is paint grade and most profiles have grain and can be stained. Call our customer service representatives to verify compatibility of staining. The use of a gel stain is required when staining flexible moulding.