Measuring Tips

PLACING AN ORDER

We offer several ways for you to place an order – by phone, fax or e-mail. Please provide the following information when ordering:

PROFILE NAME

In order to ensure the best possible match, please provide as much of the following information as possible:

- Name of the company that supplied the original wood moulding

- Whether it is MDF, finger joint or clear

- The species of wood that is being matched (for example, pine or oak)

You may also fax our office a tracing of the profile to ensure that our mouldings match exactly.

APPLICATION

We need to know how the moulding is being used – for example, half-round, arch, elliptical, curved wall.

DIMENSIONS

See diagrams for how to measure the proper dimensions for each type of application.

LENGTH OF MATERIAL

Our standard mold length is 12’. Shorter lengths can be custom made but it may be less expensive to order 12’ lengths for the items that we stock.

SPECIAL ORDER REQUIREMENTS

Examples:

- Reversing the orientation of the moulding

- Using casing on the ceiling as an accent for crown moulding

CASING

Casing is generally bent with the thick edge to the outside of the radius, but can also be speci�fied with the thick edge to the inside. When ordering, please specify if the moulding needs to be reversed.

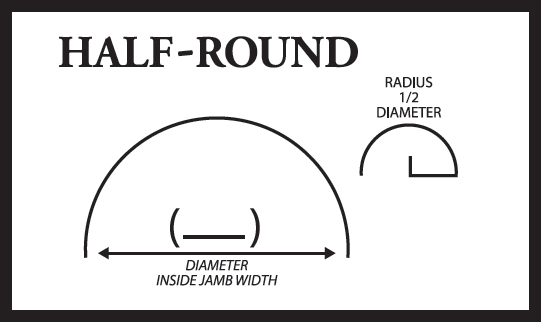

Selecting A Half Round

Sizes for half-rounds are based on the diameter (2 times the radius) of the inside jamb width. For example, a 2/0 half-round will have a diameter of approximately 24”.

Material length required for half-round (in feet) = Diameter /2 (Radius) + Casing Width x Pi (3.146) / 12

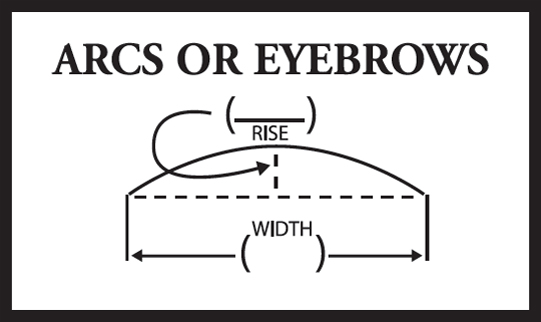

Arc/Eyebrow Moulding

For arched openings, please provide measurements for the width of the opening (inside jamb) and the center rise (do not include leg height). Templates are not required if it is a true radius opening.

Material length required for arc (in feet) = Rise x 3 + Width (both in inches)/ 12

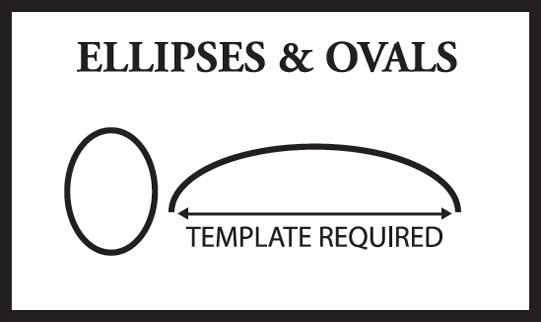

Elliptical/Oval Moulding

Casing for elliptical or oval applications must be pre-bent at our factory. � ere are limitations on how tight a radius can be created. Templates are usually required, but we have standard templates for many window and door unit manufacturers.

SIX STANDARD SIZES IN STOCK

| SIZE |

FITS INSIDE JAMB WIDTH

(Diameter) |

| 2/0 |

22” to 25” |

| 2/4 & 2/8 |

26” to 32” |

| 3/0 & 3/4 (1/8 Twin) |

34” to 40” |

| 4/0 (2/0 & 2/4 Twin) |

42” to 56” |

| 5/0 (2/8 Twin) |

57” to 66” |

| 6/0 (3/0 Twin) |

67” to 84” |

CROWN MOULDING

Crown moulding typically needs to be pre-bent during production. Please supply the following information when ordering:

- Whether the application is convex (outside radius or OSR) or concave (inside radius or ISR). IMPORTANT: Please specify if the crown is being used for a dormer window or Tudor-style roof.

- How the crown will be installed. Identify top and bottom of the pro�file.

- The radius of the wall or ceiling. Th e radius can be calculated by providing the width and rise. Please provide dimensions A, B and C from diagram above.

- If you are using a crown backer such as a ceiling plate or wall plate. Ceiling plates must be pre-bent, while wall plates use straight pieces.

BASE AND CHAIR RAIL MOULDING

Base and chair rail pro�files are typically installed with the back of the moulding to the wall. A straight standard piece is normally used unless it is a very tight radius, which may need to be pre-bent. Please specify length of material required, the profile name and the species of wood that is being matched.

S4S/JAMB

Please clearly specify how the product is being installed (for example, casing, jamb or base) so that we can determine whether to pre-bend or not. We stock most standard dimensions – 1 x 4, 1 x 6, etc. – in 8’ and 12’ lengths. Custom sizes are available with no setup charge. We also have molds for a 1 x product with wood grain (similar to a cedar texture) that can be used for interior or exterior applications. Please specify the width, thickness and length of material required and whether wood grain is needed.